CO2 Capture Plant manufacturers

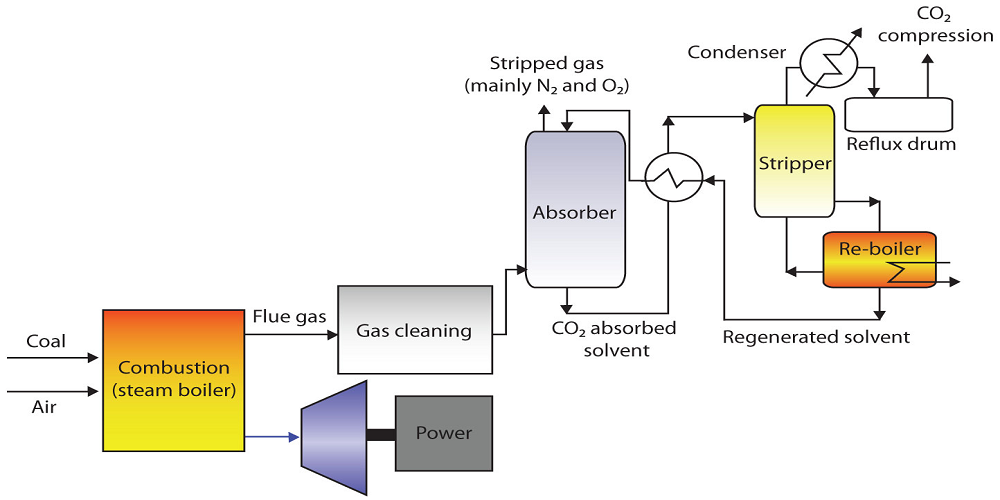

CO2 Capture Plant manufacturers design, develop and manufacture systems and technologies that capture carbon dioxide emitted by industrial and power generation processes. Their main objective is to reduce CO2 emissions and mitigate the effects of climate change by capturing and storing CO2 underground, in oceans or mineralized solids. They work closely with industries, power plants and other companies to create custom solutions that can capture CO2 from their flue gas streams. The CO2 Capture Plant manufacturers employ various techniques such as absorption, adsorption, membrane separation and cryogenic separation to capture CO2. The captured CO2 is then transported through pipelines or stored in geological formations or used for enhanced oil recovery. These plants play a key role in reducing greenhouse gas emissions and transitioning towards a cleaner energy future.

What is a CO2 Captures Plant ?

A CO2 capture plant is a facility that captures carbon dioxide (CO2) emissions from industrial processes or power generation plants and stores them in a way that prevents them from being released into the atmosphere. The captured CO2 can be stored underground or used in other industrial processes. CO2 capture plants are an important part of efforts to reduce greenhouse gas emissions and mitigate climate change.

It is the process of capturing carbon dioxide (CO2) before it enters the atmosphere, transporting it, and storing it (carbon sequestration) for centuries or millennia. Usually the CO2 is captured from large point sources, such as a chemical plant or biomass power plant, and then stored in an underground geological formation. The aim is to prevent the release of CO2 from heavy industry with the intent of mitigating the effects of climate change.[3] Although CO2 has been injected into geological formations for several decades for various purposes, including enhanced oil recovery, the long-term storage of CO2 is a relatively new concept. Carbon capture and utilization (CCU) and CCS are sometimes discussed collectively as carbon capture, utilization, and sequestration (CCUS). This is because CCS is a relatively expensive process yielding a product with an intrinsic low value (i.e. CO2). Hence, carbon capture makes economically more sense when being combined with a utilization process where the cheap CO2 can be used to produce high-value chemicals to offset the high costs of capture operations.

Proven benefits. Increased profit.

1. Modular Carbon Capture

It can achieve 90%+ capture rates and delivers industrial quality CO2 for re-use or sequestration.

2. Improved bottom line

Our technology offers the lowest corrosion rates, highest HSE standards, an uptime rate of 98+%, and can operate for more than 200,000 hours on commercial plants.

3. 30% More commercially Viable

A leader in cost-effective modular technology set to achieve $30/tonne cost of CO2 capture. Large emitters will be able to offset the cost of carbon capture with their carbon tax from as early as next year.