Pressure Vessel Manufacturers

Acid Digestion vessel Manufacturer

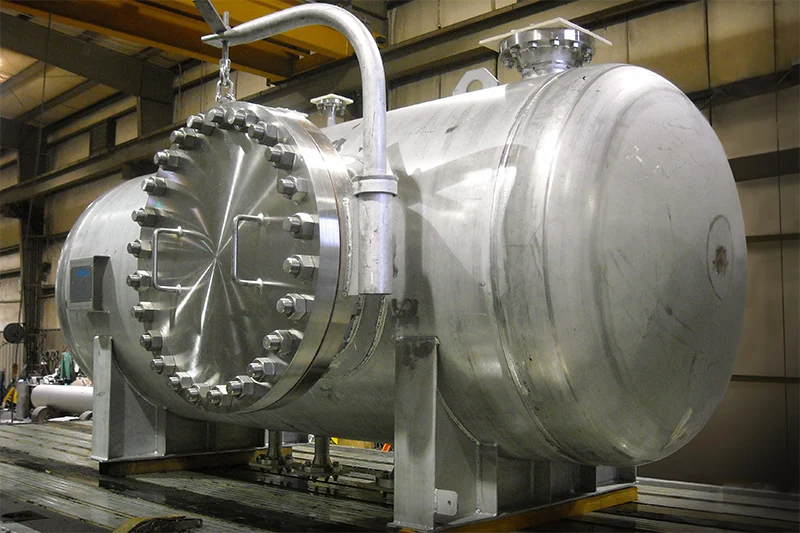

As a leading acid digestion vessel manufacturer, we specialize in crafting high-quality, corrosion-resistant vessels tailored to meet the diverse needs of laboratories and industries. Our acid digestion vessels are engineered with precision, ensuring optimal performance for sample preparation in analytical processes. With a commitment to quality and durability, our products adhere to industry standards, providing a reliable solution for acid digestion applications. Explore our range of vessels designed to withstand harsh chemical environments, guaranteeing long-lasting performance. Trust in our expertise for superior acid digestion solutions, elevating efficiency and accuracy in your laboratory processes. Choose reliability, choose NSC Industries.

What does a Pressure Vessel manufacturers do?

Pressure vessel manufacturers design, produce and assemble containers that can withstand high levels of internal pressure. These vessels are used to store and transport gases and liquids safely and efficiently. They are typically made from materials such as metal alloys or composites, and can range in size from small tanks to massive industrial vessels. The manufacturers will adhere to strict safety regulations and guidelines to ensure the vessels are safe to use in a variety of environments such as chemical plants, oil refineries and power stations. They also perform routine maintenance and cover any necessary repairs to ensure the vessel continues to function efficiently and safely over its lifetime. Ultimately, pressure vessel manufacturers play a crucial role in the safe handling and transportation of pressurized substances.

What is a Pressure Vessel ?

A pressure vessel is a container designed to hold gases or liquids at a pressure different from the ambient pressure. They can be used for a variety of industrial and commercial applications, such as storing and transporting compressed gases, chemicals, and fuels. Pressure vessels are typically made from materials like steel, aluminum, and titanium, and they are designed and certified to comply with national and international safety standards to ensure that they can withstand the high pressures without rupturing or failing.